|

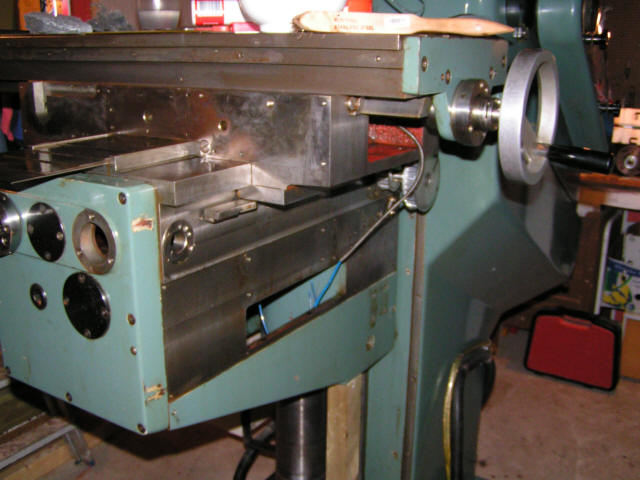

After removing the surface

rust I set out to inspect the machine the best I could.

The machine has boxways on Y and dovetail ways on X and

Z. The ways and screws looked fine on all three axes.

Here's a couple of random photos:

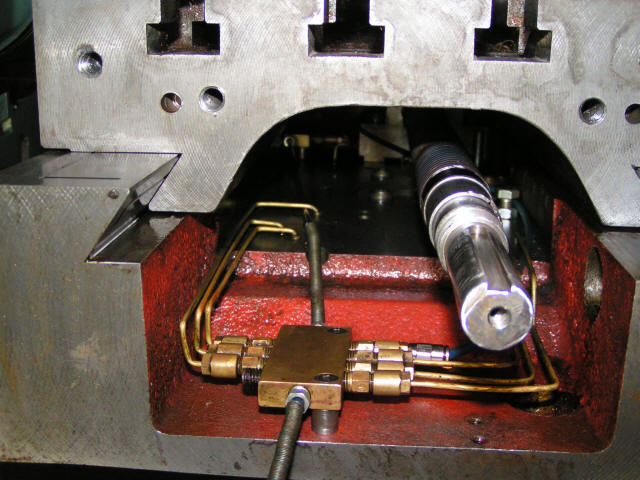

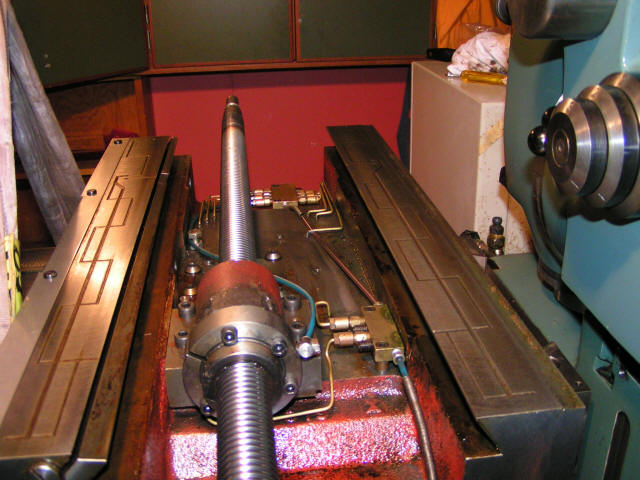

This is the Y-axis ways and ballscrew, the red/brown

junk isn't rust it's just old oil and grease....

This is the Y-axis ways and ballscrew, the red/brown

junk isn't rust it's just old oil and grease....

The next photo is a

closeup of the X-axis ballnut. The screws are 32mm in

diameter, 5mm pitch on all axes and are made by

Rexroth/STAR.

As you hopefully can see

in the next photo I was able to get the rust on the

sides cleaned up pretty good:

Here's another shot of the

left side of the X-axis with the bearingplate removed.

You can see one of the manifolds for the central lubing

system:

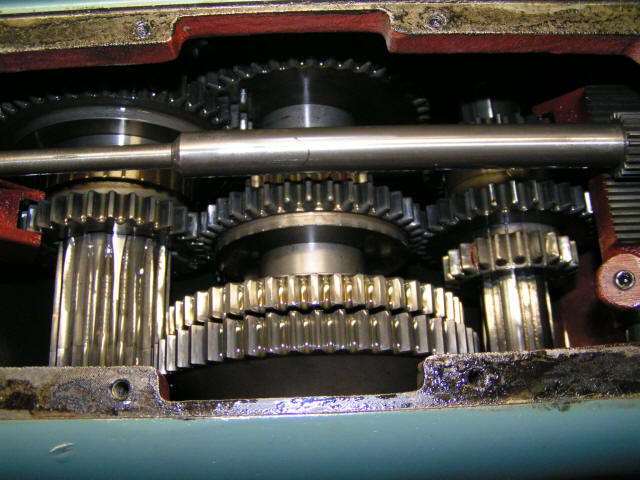

And here's a shot of the

spindle gearbox. The spindle, by the way, is a SK40

DIN2080, has 12 speeds between 44 and 2000rpm and the

motor is 4.5kW (6HP). It will eventually be controlled

by a Siemens Micromaster VFD.

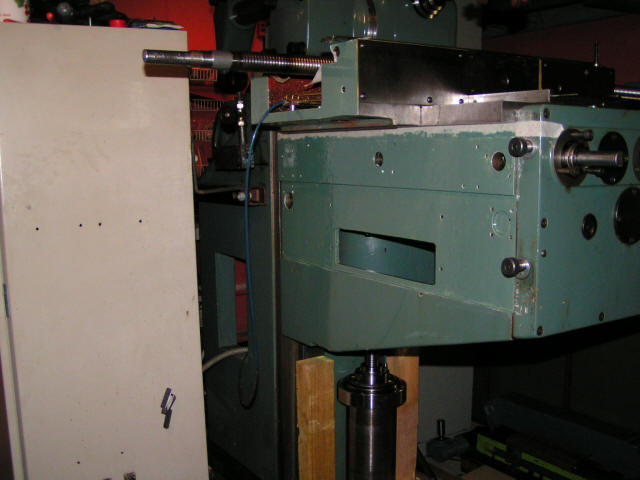

Quite early in the process

I discovered a problem with the

Z-axis. The bevel gear that drives the Z-axis ballscrew

was slipping on the shaft so I had to take that apart

and fix it. I bought an engine hoist and started by

removing the table to gain better access as well as

reduce the weight of the knee a bit:

Once I got the knee lifted

(and supported) high enough I was able to slip down the

telescopic covers, loosen the ballscrew at the top end and

thread it down into the "leg" of the knee.

After that I could remove the whole

screw jack from the base of the machine. Once that was

done it was easy to spot the problem:

As you can see the only

thing holding the end of the shaft to the ballscrew was

a single set-screw. It was also burried so deep in the

shaft (in order for the gear to fit over it) that it more

or less became like hollow pin instead of a solid screw. I replaced the setscrew with a

conical dowel pin going thru the extensionshaft and

ballscrew from one side to

the other. Hopefully it will hold up much better than

the set-screw.

Here's a shot of the sadle

with the table removed:

While having the table

removed I figured I might as well get some paint on that

bare metal on the sides of the machine, here's the

basecoat applied:

And here's the same view

with two out of three layers of paint. I brought one of

the bearingplates with me to the store for the guys to

match the new pain against. They did a pretty good job.

<Back>

<Next>

|